I'm a member of the Triumph broken axle club.

The incident occurred at low speed and without any traffic. Once was enough of a thrill for me, after the incident I immediately purchased a set of Corvair rear hubs from David Wingett

This assembly consists of a machined aluminum billet hub that holds a Corvair stub axle. The axle is connected to the TR splined shaft via a Ford-to-Chevy universal joint. This is the same basic design used by Group 44 on IRS Triumphs back in the 70's, and many folks have raced on them for years without incident. The assembly uses readily available bearings from NAPA and is fitted with 3x7/16x20 racing studs.

(note: this photo was stolen from http://www.hottr6.com/triumph/tr6drivetrain.html I'll get my own photo in short order)

Corvair Axle Conversion bearing parts list:

| Parts | Napa # |

|---|---|

| Inner Seal | 16757 |

| Outer Seal | 46460 or 21650 |

| Inner Race | M86610 |

| Outer Race | LM67010 |

| Inner Bearing | M86649 |

| Outer Bearing | LM67048 |

| U-Joint | 319 |

| Clip for Yoke | 260-10 Includes 5/16 bolts |

The billet cut 6061T Aluminum carrier hubs for a Corvair axle/flange mount to the trailing arm the same as the stock assembly. David welds up the 5 lugholes on the Corvair axle / flange then re-drill 4 new holes at 4 1/2" on center (the early Corvair axles had a 4-bolt pattern. He uses the stronger later model that has a 5-bolt pattern). The axle is magnifluxed then turned on a lath to insure that the mounting face is flat. All the bearing surfaces are polished, this makes disassembly for inspection easier. All the parts are magnifluxed, painted then assembled. The Corvair axle has a very large u-joint yoke that is splined to fit on the axle. This yoke is machined to a smaller size, to more closely match the hole in the trailing arm.

Replacement Parts availability:

The u-joint is a NAPA #319; a Chevy to Ford conversion piece. With one set of bearing caps being smaller then the other. The

stock Triumph yoke (TRF# 142437) is then machined to fit this smaller end. All the bearings and seals are readily available at

NAPA.

Problems associated with used axle yokes:

The yoke problems are: The obvious like an egg shaped hole or a dent in the hole both from a past failure. The magniflux test

will pick up fractures in the u-joint area and the splined tail. The hard one won't show up until it is mounted in the

fixture to for machining. David has found that the holes for the u-joint are not always concentric to the centerline of the

shaft. The hold is enlarged by a few thousandths so there is a very small amount to fudge.

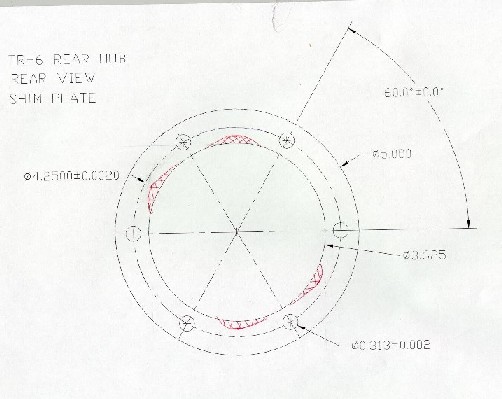

Even after machining the Corvair u-joint is still to large to pass through the hole in the swing arm. The following illustrates the sections of the swing arm that must be enlarged to accept the axle.

Orientate the new axle so that the u-joint is perpendicular to the ground . Consider the top stud to be #1. The corners will be between #1 & 2, #3 & 4, #4 & 5 , #6 & 1. This is the area that needs to be removed. If you feel the area to be removed , you'll feel a lip. It won't take much but, this lip is what needs to be removed. Take as much as is needed. And make the channels as deep as you need. Flip it over to make sure that it can go in on either side. If your using drum brakes you'll have to remove this area from the back plate also. No assembly drawing is available, however, the assembly is very straight forwarded, it's great, you can rebuild it in the paddock between sessions. To avoid pulling the hub apart IF you break a long stud. a clearance groove is cut between the # 3 & 4 studs. The grove is angled sufficiently to allow a stud to be slipped in.

David Wingett e-mail

9600 Reesee Rd

Clarkston Mi 48348

(248) 625-9478