Copyright 2004-2006 Lee Janssen

The information provided by this web page is true and complete to the best of the author's knowledge. All recommendations are made without guarantees on the part of the author. Because the quality of parts, materials and methods are beyond the author's control, the author disclaims all liability incurred in connection with the use of this information.

Braking is a complex issue that is dependant on a LARGE number of variables including hydralics, tires, weight distribution, friction material, and brake construction to name a few. The following modification should ONLY be performed by qualified mechanics as one part of an entire system upgrade. Failure to properly modify braking components will result in a poorly balanced braking system that can reduce the braking distance or make the car hazardous during panic braking. Failure to properly configure your braking system may result in personal injury or death.

The following is supplemental information to that provided by the VTR web page:

http://www.vtr.org/maintain/brake-conversion.shtml

LINK

VTR provides valuable information for TR3/3A/4/4A/250 (I don't own any of these vehicles & cannot vouch for the technical data). The VTR original printed article was written with the best information available at the time of publication. However, several omissions / corrections to the technical data were discovered after the original publication date. As one of the original authors, and source of all of the technical data, I was hoping that that VTR would want to get the story straight. Unfortunately all attempts to get VTR to correct their web page have gone unanswered. As a result I have posted the correct information here along with some additional information that you might find interesting (And you never know when those VTR rascals are going to take down their web site).

The brake modifications outlined here are a result of observations that certain brake components, intended for other vehicle applications, could be installed on a TR6. The credit goes to the following individuals where were observant enough to discover these improvements:

Front Brakes:

Two types of front calipers were used in the TR6, both have a piston diameter of 54mm.

Rear Brakes:

Two sizes of rear cylinders were used in the TR6, 0.7 inch bore fitted to US models up to 1976, and 0.75 inch bore fitted to very

late US models. The increase in the bore resulted in increased braking force at the rear wheels by 14.7%. It is very interesting

to note that the rear brakes were updated while the front remained untouched.

Brake Servo:

| year | weight lb | weight kg |

|---|---|---|

| 1969-1970 | 2317 | 1053 |

| 1971-1974 | 2277 | 1035 |

| 1975-1976 | 2334 | 1061 |

Unlike a lot of vehicles the TR6 remained approximately the same weight throughout the production run. It is doubtful that changes to the master cylinder and rear cylinders were due to a change in vehicle weight.

There are two types of forces applied to the vehicle; static and dynamic. Static force is due to gravity and dynamic force is due to the acceleration and deacceleration of the vehicle due to applied forces. In an ideal world the vehicle forces should be evenly distributed on the tires. We don't live in an ideal world.

Because the center of mass is above the road surface any acceleration transfers weight to the opposite set of wheels. Accelerate forward and the weight is transferred to the back, accelerate backwards (brake) and the weight is transferred forward. The amount of the weight transfer is proportional to the height of the center of mass above the roadway and the rate of acceleration.

On any properly designed brake system the limiting factor is the tire-to-road friction, which is proportional to the weight applied to the tire. Dynamic weight transfer during braking causes the front brakes to carry a larger percentage of the total vehicle weight and allows the front brakes to generate higher frictional forces. As a result, the front brakes are typically larger than the rear brakes.

It is important to ensure that the friction material is the same on all four wheels. The coefficient of friction for different brake compounds may vary widely with temperature. As a result a braking system that is balanced when the brakes are cold can become unbalanced when the brakes are hot. At best the braking may be compromised, at worst you can loose control and kill someone.

The Toyota calipers have two different size pistons; 1.685 and 1.345 inches diameter. The total piston area for each side of the caliper is 1.16 in2, which is effectively the same as the 1.13 in2 for the TR6 piston. Braking force is the product of the coefficient of friction of the braking material times the caliper piston force. Since the piston force is proportional to the piston area we can make the following assertion:

Addition of Toyota 4 piston calipers will NOT improve braking distances. The Toyota calipers may be more fade resistant, however, if all other variables are fixed, the braking distance will remain the same.

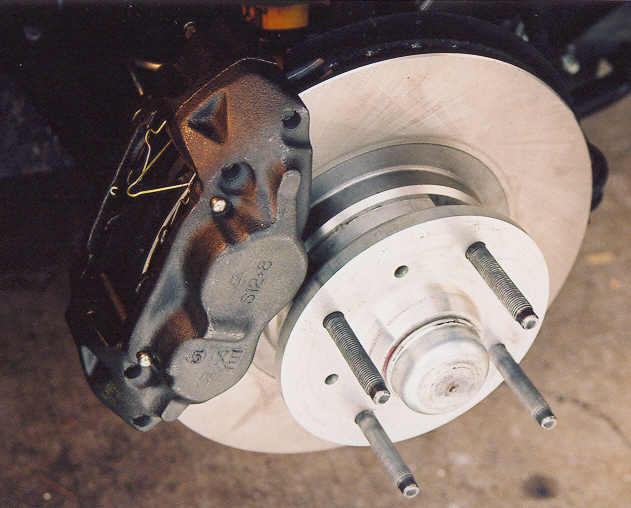

This is a photo of Toyota 1979-83 four wheel drive pickup (non-diesel) front caliper installed on a TR6 front axle. Note the hard brake line makes several bends to make it possible to access the caliper bolt without removing the brake line.

This illustrates the stock brake and pad on left and the Toyota on the right. The total lining area for the Toyota is approximately 27.8 in2 or 179 cm2, a 34% increase over the lining area for the TR6. This increased area combined with the large size of the caliper may help reduce pad and caliper temperatures, and thereby reduce brake fade.

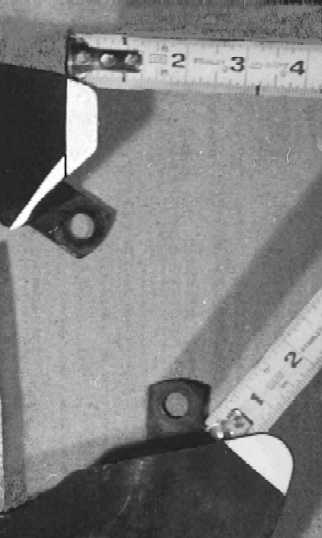

You can see that the late version has about 0.008 tolerance between the bolt and the hole. The early version has about 0.045 tolerance which is way too much!

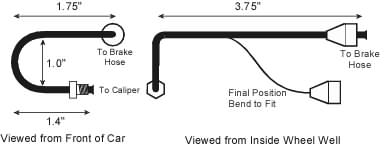

This schematic illustrates the construction of the hard brake line.

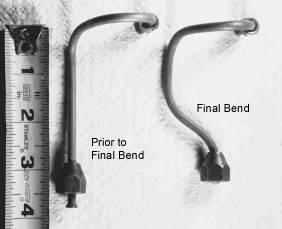

The left tube is prior to the final bend, the right tube is after final bending. The bend allows access to the caliper bolt.

The dust shield must be trimmed to fit. The white region illustrates the cuts that need to be performed. 1/2 inch is trimmed from the top end, 5/8 inch is trimmed from the bottom end. A small sliver is removed next to the upper shield attachment.

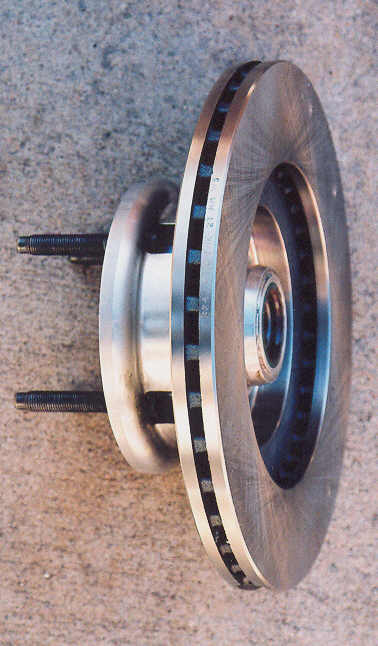

Installation of Toyota Cressida vented brake rotors on a TR6. Note that the anti-rattle springs are installed, these were later removed due to an apparent caliper spread issue.

A side view of the vented rotors mounted on Southwick Machine & Design Hubs. These rotors have a slight greater standoff distance from the trunion when compared to stock.

The following was submitted to me by Hugh Barber, Hollister, CA, '73 TR6. Thanks Hugh!

This conversion uses vented rotors from a 1986-1988 Toyota Cressida Front Rotor (Sedan Only). The inner hole of the Toyota rotors

needs to be machined to 3.125" (this required removal of 0.130 inches diameter, 0.065 radius). The bolt holes in the

Cressida rotors are the same as the TR rotor and do not need modifying.

Advance Auto parts 4/2006 price: $53.48 each (4/06)

The Toyota calipers are 4-piston units from a 1988- April 1989 Toyota 4-Runner, 4WD, 4Cyl. They look the same as the non-vented Toyota calipers; they're just wider to fit the vented rotors.

Advance Auto parts 4/2006 price: $37.48 each w/ a $25 core (4/06)

You may also need to purchase a fitting kit (pins, shims, etc) for the calipers and brake pads.

Once the rotors are machined, installation was nearly identical to the standard 4 pot process outlined above. The only item to

note is that the rotors have a thickness of 0.87 inches; the calipers have a slot width of approximately 0.925 - 0.945 inches.

This only provides you with a caliper - rotor clearance of 0.0275 inches per side. Hugh Barber's notes indicated that some

installations required shimming with AN washers. Shimming was required in my application (caliper body interfered with the

rotor). However, I opted to simply grind the calipers to enlarge the slot width to 0.985 inches. This eliminated the need for

shimming and provided additional rotor - caliper clearance. The ground surfaces were then coated with high temperature black

paint.

I noted that the anti-rattle springs are fairly stiff and they appeared to increase brake pedal travel due to caliper spreading.

As a result, I removed the anti-rattle springs from my final installation.

Increasing the cylinder size on the rear brakes has been demonstrated to reduce stopping distances by approximately 11%.

The top cylinder with casting number 304170 is a 0.70 inch cylinder for a TR6. The lower cylinder with casting number 64670475

is a 0.875 inch cylinder. for all Morgans from 1959 - 1988 (+4, 4/4, +8) and Sunbeam Alpine series 1 & 2.

Part numbers are:

As of 7/2004 the parts supplied by Victoria British are the correct casting but without the Girling part number. This suggests that the part is now being re-manufactured at an affordable cost (about $30).

The 0.875 inch bore provides 56% more pressure to the shoes than the stock 0.7 inch bore, and 36% more pressure than the very late model 0.75 inch bore.

This is a photo of an installed stock TR6 cylinder.

This is a photo of an installed Morgan cylinder. The major difference (other than the size of the cylinder) is the retaining tangs that help engage the brake shoe. Note that the tangs do not change the shoe position they simply limit lateral motion.

Additional information on braking systems:

"Brake Handbook" by Fred Puhn, HPBooks 1985, 176 pages. (may be out of print)

"Gimme a Brake" By James Walker Jr. & Tom Mccready, Grassroots Motorsports,

Feb 2004, vol 21 No 1 page 95-103